Heat Pump Myths Debunked: What Industrial Buyers Need to Know

Despite growing adoption worldwide, industrial heat pumps are still surrounded by myths and misconceptions that prevent businesses from making informed decisions. As energy costs continue to rise and sustainability becomes non-negotiable, it's time to separate fact from fiction.

Whether you're in automotive manufacturing, pharmaceutical production, or food & beverage processing, understanding the truth about heat pump technology is critical for your energy strategy.

💡 Quick Reality Check

Industrial heat pumps are now successfully operating in extreme climates from -25°C to 45°C ambient temperatures, delivering COPs of 3.5-5.0 while reducing energy costs by 40-70% compared to traditional heating methods.

Myth #1: "Heat Pumps Don't Work in Cold Weather"

The Myth

Many buyers believe that heat pumps become ineffective or stop working altogether when outdoor temperatures drop below freezing, making them unsuitable for industrial applications in colder regions.

The Reality

Modern industrial heat pumps are engineered to perform efficiently even in sub-zero temperatures. Advanced refrigerant technology, enhanced vapor injection (EVI) compressors, and sophisticated control systems enable today's heat pumps to operate effectively down to -25°C ambient temperature.

Key facts:

- Air-source heat pumps with EVI technology maintain COP values of 2.5-3.5 even at -15°C

- Water-source heat pumps remain unaffected by air temperature, drawing heat from groundwater or process water that maintains stable temperatures year-round

- Hybrid systems combine heat pumps with backup heating to optimize efficiency across all temperature ranges

- In automotive plants across Northern India, heat pumps successfully operate during winter months, maintaining consistent hot water supply at 80-90°C

Industrial Insight: A pharmaceutical facility in Himachal Pradesh operates an industrial heat pump system throughout winter, achieving 65% energy savings compared to their previous diesel boiler setup.

Myth #2: "Heat Pumps Are Too Expensive"

The Myth

The upfront cost of industrial heat pump systems is often perceived as prohibitively high, leading buyers to stick with conventional boilers or electric heaters.

The Reality

While the initial investment for heat pumps is typically higher than traditional systems, the total cost of ownership tells a completely different story. When you factor in operational savings, maintenance costs, and lifespan, heat pumps often provide superior financial returns.

Financial breakdown:

- Payback period: Most industrial installations achieve ROI within 2-4 years

- Operating costs: 40-70% lower than conventional heating systems (see our detailed cost comparison)

- Maintenance: 30-50% less maintenance compared to combustion-based systems

- Lifespan: 15-25 years with proper maintenance (compared to 10-15 years for boilers)

- Incentives: Government subsidies and carbon credits can reduce initial costs by 20-40%

📊 Real Case Study: Chemical Manufacturing

A chemical processing facility in Maharashtra invested ₹45 lakhs in an industrial heat pump system. Annual energy savings of ₹18 lakhs resulted in a 2.5-year payback period, with projected 15-year savings exceeding ₹2.7 crores.

Calculate your own ROI →Myth #3: "Heat Pumps Can't Produce High-Temperature Hot Water"

The Myth

There's a widespread belief that heat pumps can only deliver lukewarm water (40-60°C), making them unsuitable for industrial processes requiring high-temperature water.

The Reality

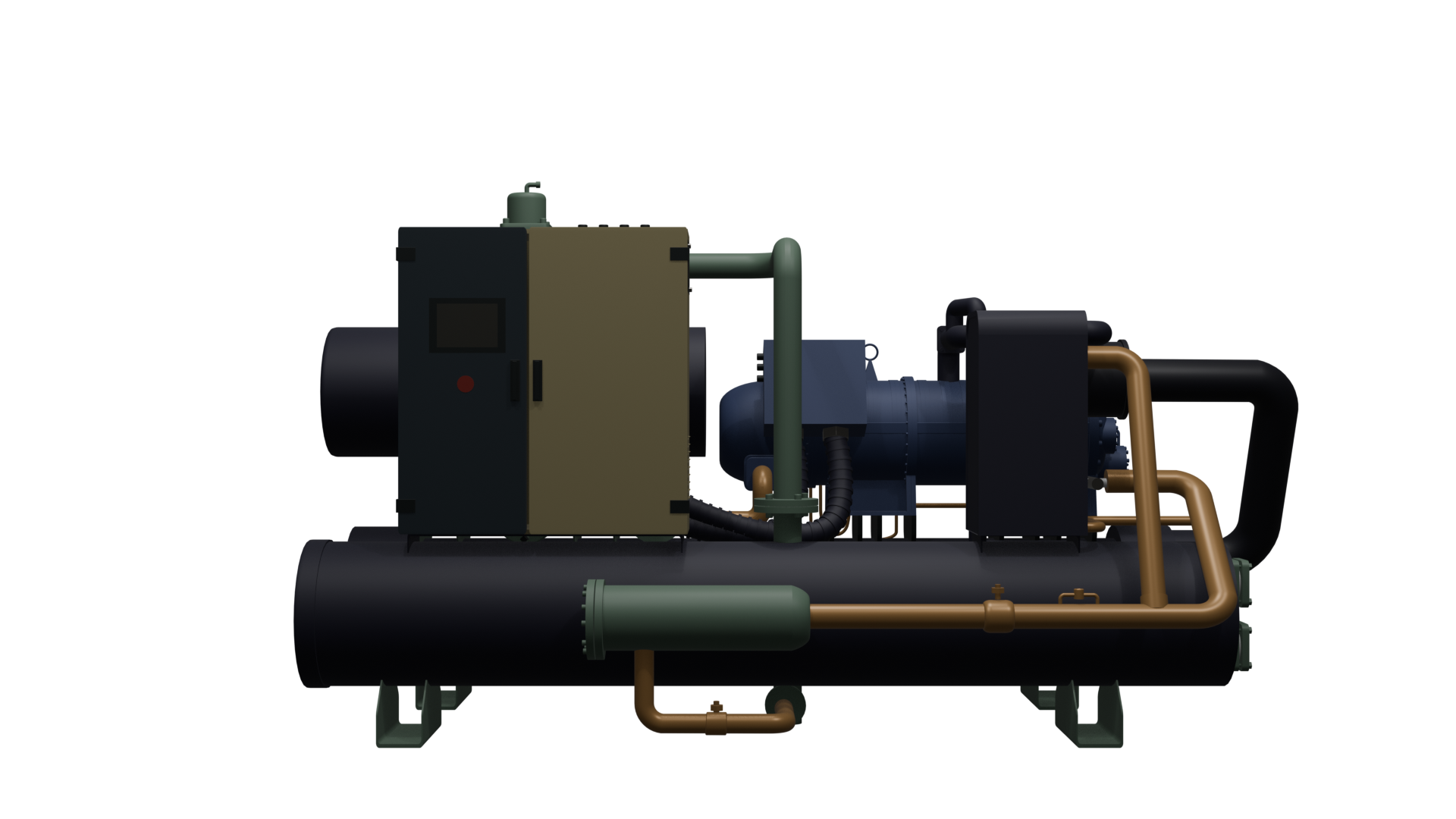

High-temperature industrial heat pumps are specifically designed to deliver water temperatures of 80-90°C and even higher with cascade systems. These systems are already widely deployed across demanding industrial applications.

Temperature capabilities:

- Standard high-temp models: Deliver 75-85°C consistently

- Advanced systems: Achieve 90-95°C output temperatures

- Cascade configurations: Can reach 120°C+ for specialized applications

- Process integration: Can utilize waste heat to boost output temperatures further

Industries successfully using high-temperature heat pumps:

- Food & Beverage - Pasteurization, process heating, sterilization

- Automotive - Parts washing, paint booth heating, pre-treatment processes

- Pharmaceutical - Distillation, formulation heating, equipment sterilization

- Paint Manufacturing - Resin processing, mixing operations

Myth #4: "Heat Pumps Require Constant Maintenance"

The Myth

Some facility managers worry that heat pumps are complex machines requiring frequent maintenance, specialized technicians, and costly repairs.

The Reality

Industrial heat pumps are actually remarkably reliable and require less maintenance than combustion-based heating systems. With no flames, no combustion byproducts, and fewer moving parts, heat pumps are inherently simpler and more durable.

Maintenance comparison:

- Heat pumps: Quarterly filter checks, annual professional service, refrigerant inspection every 2-3 years

- Boilers: Monthly combustion checks, quarterly cleaning, annual safety inspections, frequent burner adjustments, water treatment monitoring

- Downtime: Heat pumps average 95-98% uptime vs. 85-92% for conventional boilers

Learn more about our comprehensive maintenance programs designed to maximize system reliability and lifespan.

Myth #5: "Heat Pumps Are Only for Small Applications"

The Myth

Many believe heat pumps are only suitable for residential or light commercial use, not for large-scale industrial operations requiring megawatts of heating capacity.

The Reality

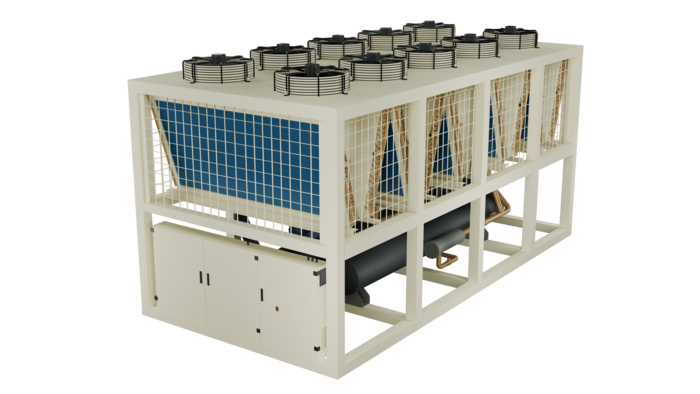

Industrial heat pump systems are scalable to virtually any size requirement. Multiple units can be configured in parallel to deliver multi-megawatt heating capacities for the largest industrial facilities.

Scaling capabilities:

- Single units: 50 kW to 500+ kW heating capacity

- Modular systems: Multiple units delivering 5-20 MW+

- Centralized plants: Can replace entire boiler houses

- Distributed architecture: Zone-specific heating for improved efficiency

Success Story: A major steel processing facility deployed a 3.5 MW heat pump system to replace their aging coal boiler, now heating 15,000 liters of process water hourly while cutting energy costs by ₹2.8 crores annually.

Myth #6: "Heat Pumps Don't Work in India's Climate"

The Myth

Some buyers believe that India's hot, humid climate or extreme regional temperature variations make heat pumps less effective or impractical.

The Reality

India's climate is actually ideal for heat pump technology, particularly air-source systems. High ambient temperatures improve heat pump efficiency, while water-source systems remain unaffected by climate variations.

India-specific advantages:

- Higher average temperatures mean better COP values year-round (4.0-5.5 typical)

- Abundant groundwater in many regions perfect for water-source heat pumps

- Industrial waste heat availability from manufacturing processes

- Extended operating seasons with minimal cold weather challenges

- Coastal facilities can leverage seawater as heat source

Heat pumps are successfully operating across India's diverse climates - from hotels in Kerala to manufacturing facilities in Punjab, proving their versatility and reliability.

Myth #7: "Installation Is Complicated and Disruptive"

The Myth

Facility managers often fear that installing an industrial heat pump will require extensive downtime, major facility modifications, and disrupt ongoing operations.

The Reality

With proper planning and experienced installation partners, heat pump systems can be installed with minimal operational disruption. Modern integration techniques allow for phased installations and parallel operation during transition.

Installation best practices:

- Phased rollout: Install during planned maintenance windows

- Parallel operation: Run new system alongside existing infrastructure during testing

- Modular installation: Deploy one unit at a time to minimize risk

- Pre-fabricated systems: Reduce on-site installation time by 50-70%

- Typical timeline: 2-6 weeks from site preparation to full operation

Our system integration specialists work closely with your team to ensure seamless deployment with zero unplanned downtime.

Myth #8: "Heat Pumps Are Just a Trend"

The Myth

Skeptics view heat pumps as a passing fad driven by temporary environmental concerns rather than a fundamental shift in industrial heating technology.

The Reality

Heat pumps represent the future of industrial heating, driven by irreversible economic and regulatory forces. The technology is mature, proven, and backed by decades of successful industrial deployment worldwide.

Market indicators:

- Global market growth: Industrial heat pump market projected to reach $5.2 billion by 2030 (CAGR 12.4%)

- Technology investment: Major manufacturers investing billions in R&D and production capacity

- Regulatory support: Carbon pricing and efficiency mandates accelerating adoption

- Corporate commitments: Fortune 500 companies setting aggressive decarbonization targets

- Energy costs: Rising electricity grid efficiency vs. fossil fuel price volatility

Learn more about the fundamental technology that makes heat pumps the clear choice for sustainable industrial heating.

The Bottom Line: Making Informed Decisions

Industrial heat pumps have evolved from niche technology to mainstream solution, backed by decades of engineering advances and real-world performance data. The myths persist largely because buyers rely on outdated information or experiences with early-generation residential systems.

Key takeaways for industrial buyers:

- Do your homework: Base decisions on current technology, not 10-year-old assumptions

- Run the numbers: Use our ROI calculator with your actual utility rates and load profiles

- Visit operating installations: See similar applications in your industry

- Consult experts: Work with experienced heat pump specialists who understand industrial processes

- Consider total cost: Look beyond capital cost to 15-year operational savings

- Think long-term: Factor in energy price trends and carbon regulations

- Start smart: Pilot projects minimize risk while proving performance

🎯 Ready to Separate Fact from Fiction for Your Facility?

Our application engineers will analyze your specific heating requirements, run detailed performance projections, and provide a no-obligation feasibility study based on your actual operating conditions.

What you'll receive:

- Site-specific heat pump sizing and system design

- Accurate ROI calculation with your utility rates

- Performance guarantees and efficiency projections

- Comparison with your current heating system

- Implementation roadmap and timeline

Explore More Resources

📊 Compare Systems

See how heat pumps stack up against boilers in real-world cost analysis.

Read comparison →🧮 Calculate ROI

Use our detailed calculator to project savings for your facility.

Calculate savings →Get the Facts for Your Facility

Schedule a free consultation with our heat pump specialists. We'll provide honest, data-driven answers to your specific questions and concerns.